Does Your Solar Site Need a DC Health Check?

April 26, 2022

Recurring energy losses, in the one to four percent range, are a good indicator that a combination of small safety and production issues are starting to emerge in your solar power plant. Even well-maintained sites can encounter DC health issues as many solar sites or sections of solar sites are not under constant supervision.

DC array issues are often an overlooked contributor to potentially significant amounts of lost energy and will eventually cause safety issues.

By applying a balance of machine learning analysis techniques on the site production data and periodic visual inspections, it’s possible to develop the insights necessary to identify the source of losses.

Finding and Correcting DC Health Issues

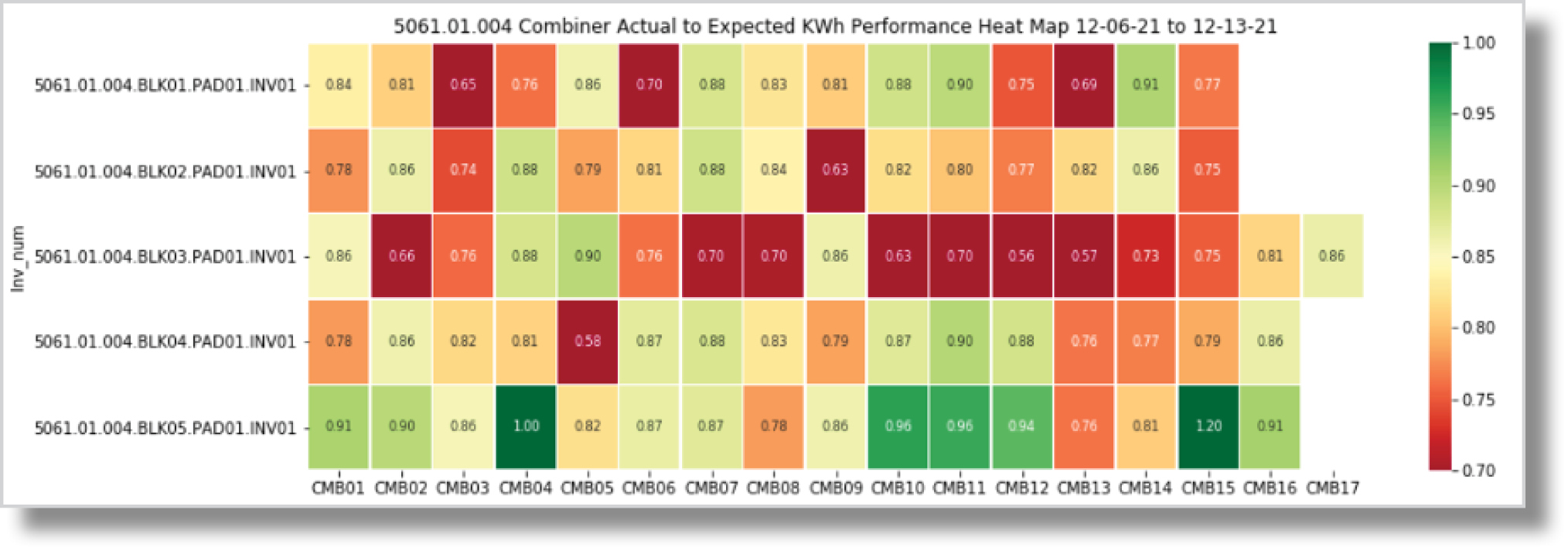

Pearce Renewables recently analyzed and optimized DC health for a large utility-scale solar portfolio owner who was experiencing productivity losses across different parts of their system. A quick assessment of combiner box performance, using a heat map technique below, highlighted the issue. From here we were able to a deeper analysis to develop the Pareto of lost energy causes.

HEAT MAP HIGHLIGHTS PROBLEM AREAS - The heat map above shows the initial combiner box performance at a site that was experiencing productivity losses. The color key, on the right, makes visual identification of issues easy.

Our analysis revealed several issues with conduit seals, damaged wires, metal bands, wire management, overheating, unused, and under-torqued connectors. Often there are other critical issues found in our analyses:

- Design errors including string sizing, fuse sizing, and conductor sizing or excessive length (increased resistance) – contribute to voltage drop and over-current on the fuses

- Inaccurate combiner heat map string counts

- Poor wire management

- Proper grounding

- Workmanship and faulty or improperly assembled PV connectors

- Moisture intrusion into equipment, conduits, connectors, etc.

- Vegetation shading or soiling

- High heat, temperature derate conditions

- Module degradation and other module performance issues

Several issues were found, each contributing to the energy losses the site was experiencing.

After taking the following actions site production returned to expected levels:

- String counts were verified throughout the recent CMB preventive maintenance

- Blown fuses were documented and replaced during CMB preventive maintenance

- Unused pigtails were removed (source of moisture-related ground faults) during CMB preventive maintenance

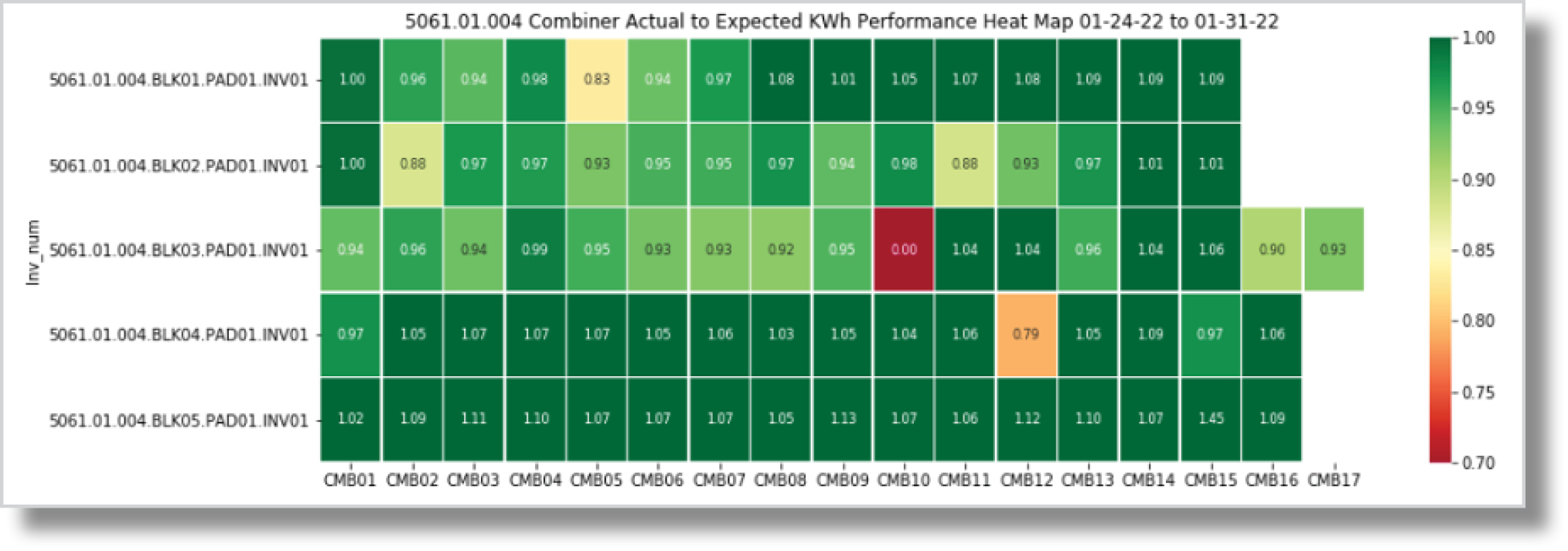

IMPROVEMENTS ARE OBVIOUS - After Pearce corrected the issues on the site, the heat map shows the transition from red/yellow/orange boxes to green boxes.

Develop and Implement a DC Health Strategy

DC health issues often originate in the design and construction phase of a solar project. Once the site is commissioned, it can become much more difficult to hold the design/build contractor responsible for energy losses. A solid DC maintenance strategy can highlight EPC and OEM issues before the warranties expire and ensure owners get what they paid for when the system was built. Beyond the end of warranty compliance and recovery of energy losses, comprehensive DC health acts as a predictive indicator of future issues. With this insight, owners and operators can plan for parts, services, and support to keep their plants operating at full capacity.

Downloadable Copy

Download our Case Study, Does Your Solar Site Need a DC Health Check here.